HOW IT’S MADE

Here’s glimpse of what it’s like to mix your passion with the capabilities of your workshop.

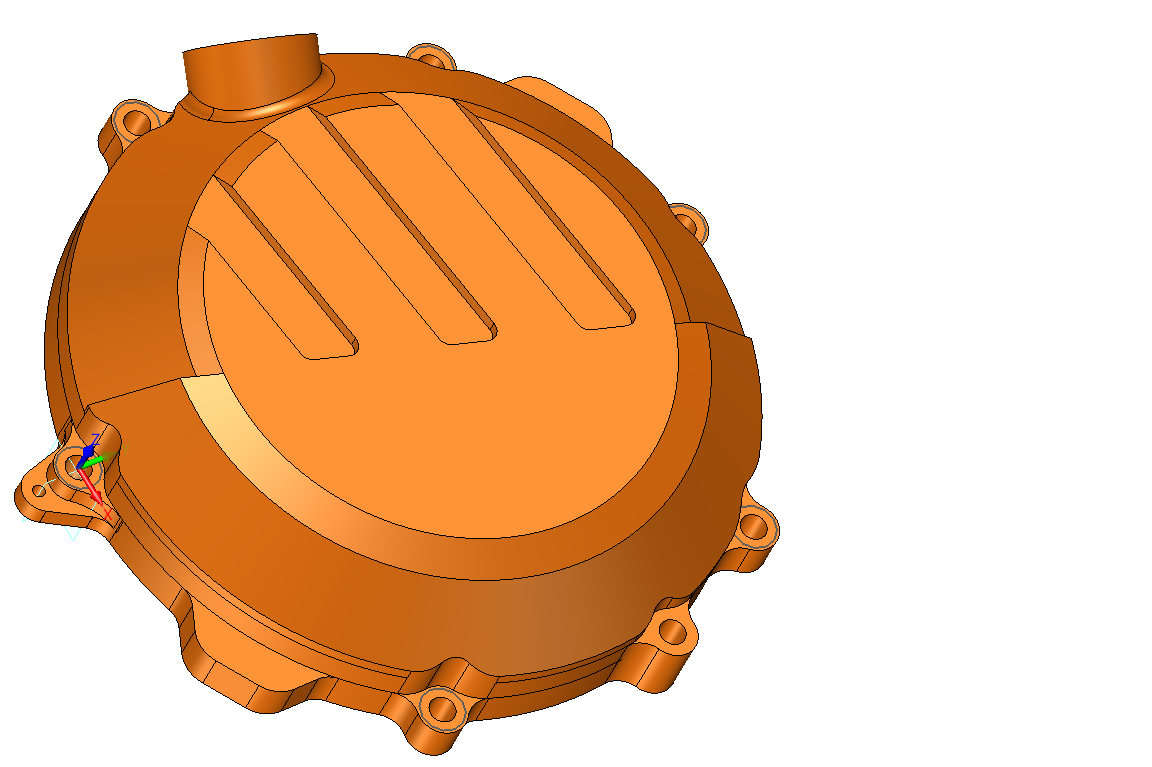

DESIGN THE IMPROVED VERSION

Our product needs to address some specific needs and add extra functionality or improve the existing OEM parts. We need to create parts that are lighter, stronger, offer a higher degree of protection or simply make the machine look better. In an ideal world, all of the above in the same part.

3D measure/scan the bike area where the new part is supposed to perform its function.

Based on the 3D Measurements we start the design.

RELEASE THE PROTOTYPE

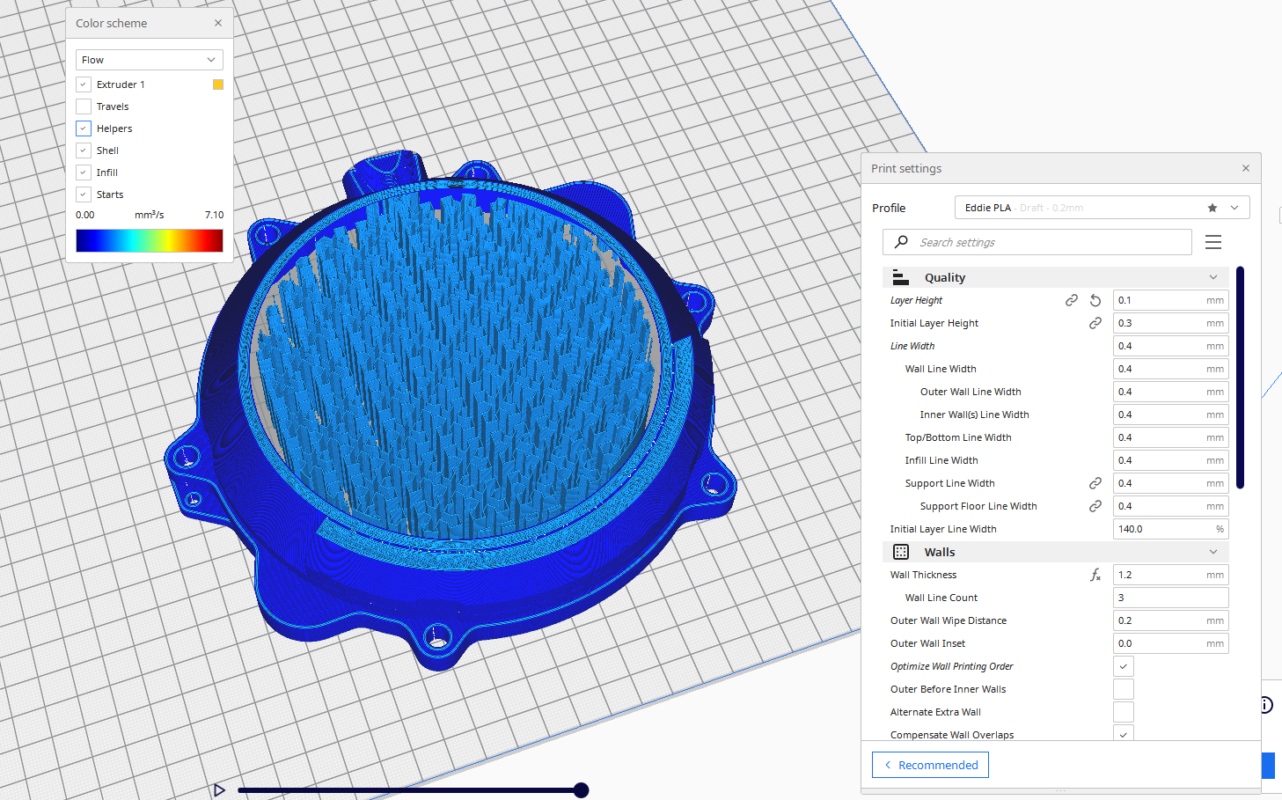

At this stage we get to the nerdy side of things: depending on the part’s purpose decide what is the function over looks ratio, what are the required strength constrains, all that to get to things as material type, manufacturing options, programming and machining strategies.

Once we get to a satisfying intermediary result, we create a functional prototype to test on the bike. For that purpose, depending on the specific need we 3D print or mill the first test part.

See our workflow

Design

We always try to be where action is. Collect impressions, experiences.

We try to turn all that into better parts.

Manufacture

Base on our prototype designs, we manufacture the parts to the best of our knowledge in our workshop

Ride and Test

Once finished, we test the parts. We gather data and if necessary get back to the drawing board. Test again. Repeat until we get the required result

INSTALL AND TEST IT !!!

We install the prototype, analyze and decide if there’s any modification to be performed while still in development phase.

If everything looks good, we do a test run of the product on our CNC machines, send the parts out to be surface treated and define the graphic customization options for that specific part.

Once we get to the production ready version we send out a few parts to experienced racers for a real product testing and feedback.